Before answering this question, let's take a look at what a double coating process is.

In industry, it refers to the application of two coats on the same substrate surface, although double coats can provide many benefits. For example, it can more effectively prevent metal from being corroded, rusted, and oxidized, and greatly prolong its service life and corrosion resistance.

But double-coating also means using more paint, increasing construction and production time, and costing more. In addition, if the primer is too thick, the topcoat will be unbalanced or the effect will be worse, if it has a clear coat , will cause the surface to appear milky white. This affects the final finish. Moreover, the requirements for the construction level are relatively high, otherwise it is easy to produce bubbles and other phenomena.

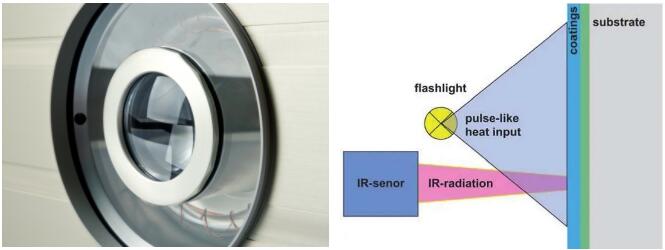

Back to the problem that the coating thickness gauge can measure the thickness of the double-coating process. Since it is a coating on the metal, it can be used by the coating thickness gauge to measure the magnetic effect, eddy current effect or thermal imaging principle.

However, we have encountered many industrial users who need to measure the thickness of a certain layer separately. Generally, there are two solutions.

The first one:

Choose magnetic or eddy current effect coating thickness gauges, which are cheap and accurate, but not suitable for double-coated parts with high curvature. If you need to measure the thickness of a certain layer, you need to wait for the first layer to dry before measuring. calculate.

The second one:

Choose a photothermal coating thickness gauge. The equipment is expensive, but the accuracy is acceptable. Dry and wet coatings can be used without waiting for the coating to dry.

Of course, there are other measurement methods such as laser and gold, but the above two are cost-effective solutions for non-destructive measurement and easy operation.