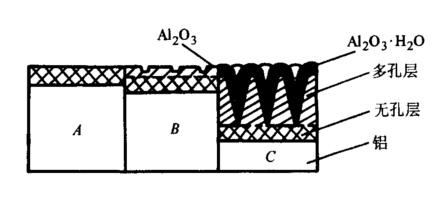

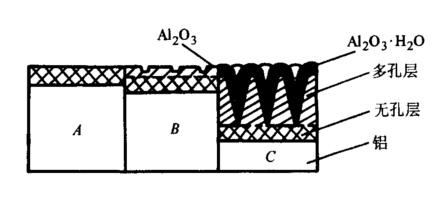

Anodized film often refers to a protective film layer on aluminum or alloy-based substrates, which can bring such substrates properties such as corrosion resistance, wear resistance, adsorption, and insulation. In an acid solution, when the aluminum anode is oxidized under the action of an external current, two processes occur at the same time: the formation of the oxide film and the dissolution of the oxide film. When the film formation speed exceeds the film dissolution rate, the actual oxide film on the aluminum surface , Which forms an anodic oxide film.

The anodic oxide film is composed of two layers. The outer layer is called the porous layer, which is thicker, loose and porous, and has low resistance. The inner layer is called the barrier layer (also known as the active layer), which is thinner, denser, and has high resistance. Can the thickness of the anodic oxide film be measured with a coating thickness gauge?

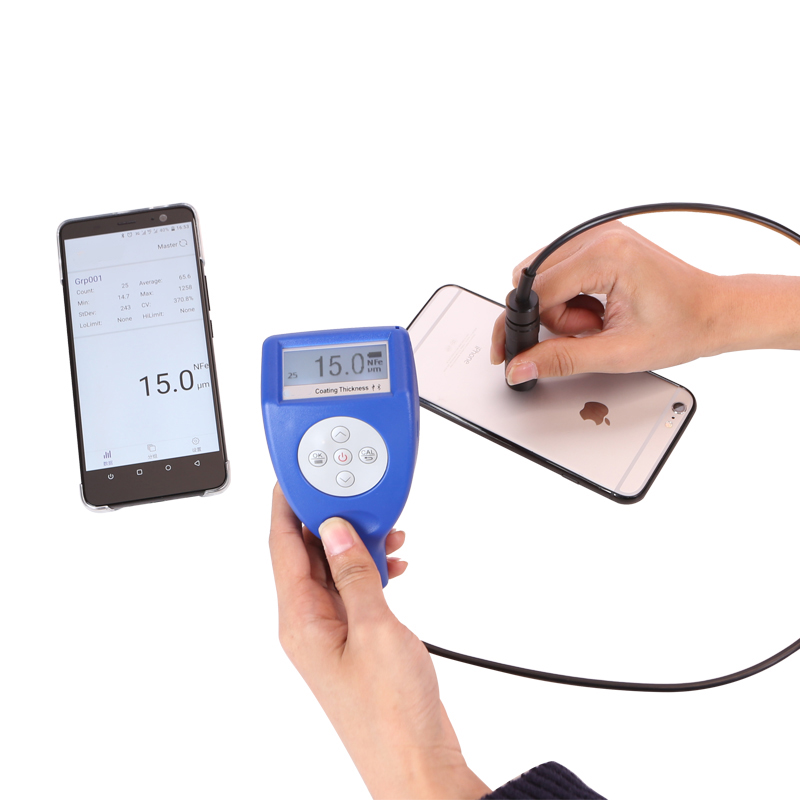

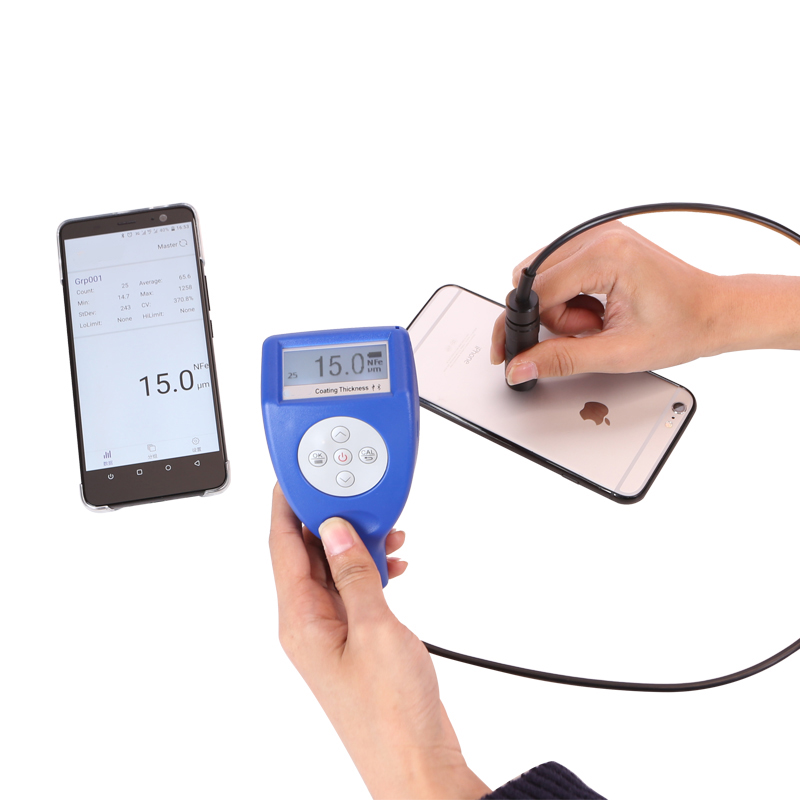

Pictured: Guoou GTS820NF eddy current coating thickness gauge measures the thickness of the anodic oxide film on the back cover of the Apple mobile phone

The answer is that the thickness of the anodic oxide film can be measured with an eddy current coating thickness gauge.

In the industry, the thickness of the oxide film is generally about 10um (micrometer), the pore diameter of the oxide film is between 100nm~200nm, and the pore distance is between 300~500nm. It can be seen that, in order to measure the thickness of the anodic oxide film, a high-precision instrument is required, and the coating thickness gauge can measure the coating between 0-5000um, the principle of the eddy current effect of the instrument. The instrument uses a high-frequency AC signal to generate an electromagnetic field in the probe coil, and when the probe is close to a conductor, an eddy current is formed in it. The closer the probe is to the conductive substrate, the greater the eddy current and the greater the reflection impedance. This feedback action represents the distance between the probe and the conductive substrate, that is, the thickness of the non-conductive coating on the conductive substrate.

Eddy current sensors have the advantages of large measuring range, high sensitivity, simple structure, strong anti-interference ability and non-contact measurement. They are widely used in various fields of industrial production and scientific research.