Fiber Reinforced Plastics (FRP), also known as Glass Reinforced Plastics (GRP), need to be coated, and the appropriate coating material must be selected and the FRP surface properly treated to ensure long-term performance.

Applications of Fiber Reinforced Plastics (FRP)

FRP is often used in highly corrosive exposure environments because it is inherently resistant to corrosion and does not rust like steel. So why cover it with a protective coating? One of the main reasons is to provide UV protection. Exposure to UV light breaks the carbon chain of the polymer, which degrades the resin at the molecular level. An analogy for degradation is the chalking of epoxy coatings when exposed to sunlight. In the case of FRP, as the outer layer continues to degrade, the glass fibers will be exposed and the mechanical properties of the laminate will decrease. If the surface is degraded by UV light, we can apply a new coating to stop it from degrading further.

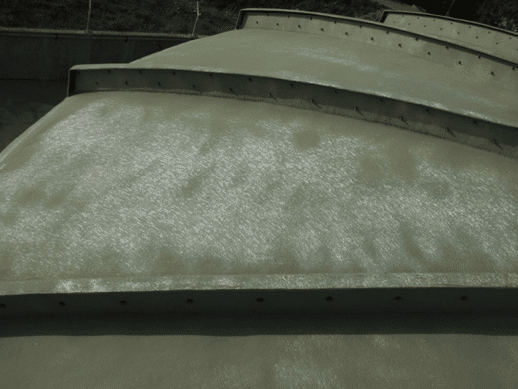

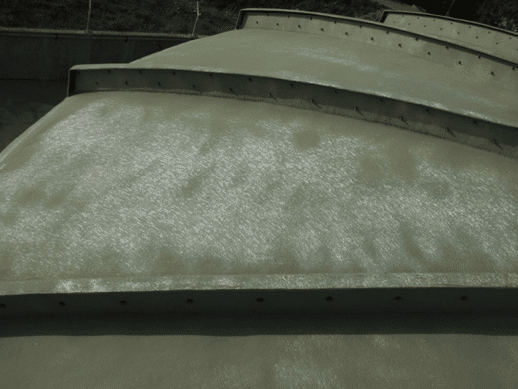

Photo 1, UV light degrades the FRP resin on the top of the tank, exposing the glass fibers. A protective coating on the FRP can prevent this degradation.

FRP coating is applied to match the facility's color coding. Many large industrial facilities have specific color codes for equipment and piping, such as red for fire protection systems, blue for cooling water, and yellow for natural gas. FRP can be easily painted to match the facility's color scheme.

FRP also needs to be painted for aesthetics. Over time, FRP will fade and the gloss will decrease. If required, the coating will give the component a new look, including high gloss.

The use of FRP with different coatings

FRP is available in a variety of general purpose coating types. Select a specific coating system based on expected environmental exposures such as chemicals or UV light. The following are several types of coatings commonly used in FRP:

Gel Layer - Gel coats are typically used in the manufacturing process. It is a topcoat selected from the same base resin type used in the manufacture of the product, with the addition of additional UV stabilizers and pigments. There is no reinforcing fiber material in this coating, nor does it provide structural properties to the assembly. Before injection of FRP material, a gel layer can be applied on the surface of the mold, or on the surface of the finished product by spraying, brushing or roller coating. Examples include exterior fiberglass panels and pleasure boats that use UV-stabilized gel layers.

Several water-based acrylic coating systems are also suitable for FRP. Acrylic paint is one-component, easy to apply, and does not require the addition of organic solvents other than water during construction. They contain virtually no volatile organic compounds (VOCs), making them ideal for use in areas with strict VOC emissions restrictions. UV resistance, color retention and chalk resistance are generally good, but may vary in different products. For exposure to harsher working environments (chemical/marine), a better performing coating system is recommended. Depending on the paint variety, a bonding primer may be required. Specific product requirements should be consulted with the coating manufacturer and the product data sheet.

Epoxy resin systems typically have excellent chemical resistance and are typically used where chemical exposure is expected. Epoxy resins are two-part curing systems that require mixing prior to use. While water-based epoxies can be used, solvent-based epoxies are more common. Generally speaking, epoxy resins have poor UV resistance and will whiten and fade in sunlight. If the expected exposure is likely to be sun exposure, a topcoat such as polyurethane should be applied over the epoxy coating.

Polyurethane coatings consist of two components and generally have good chemical resistance. Unlike epoxy resins, polyurethanes have excellent UV resistance and are suitable for outdoor use. They can be used as a topcoat for epoxy or applied directly to FRP.

How to measure the thickness of FRP coating

Because it is a non-metallic material, when we measure its total thickness, we can use an ultrasonic thickness gauge to judge whether the engineering anti-corrosion requirements meet the standards and the corrosion of the FRP coating through the thickness measured by the instrument.

Summarize:

FRP-applied topcoats can improve UV and chemical resistance, match color-coding regulations for pipes and containers, or improve aesthetics. Traditional industrial coatings such as acrylic, epoxy and polyurethane can be used for FRP coatings. Before applying the paint, the surface must be cleaned, dried and roughened to ensure good adhesion.